Eco-Friendly Vinyl Cladding

The Natural Choice

Reducing our carbon footprint

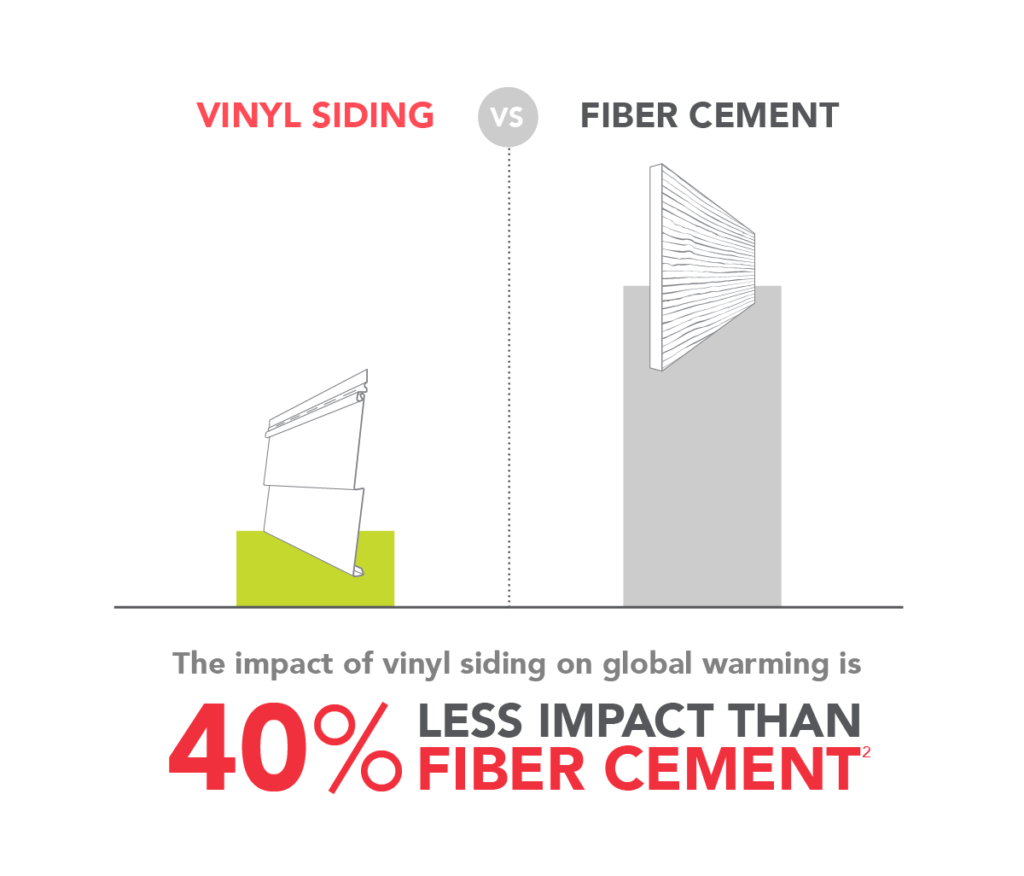

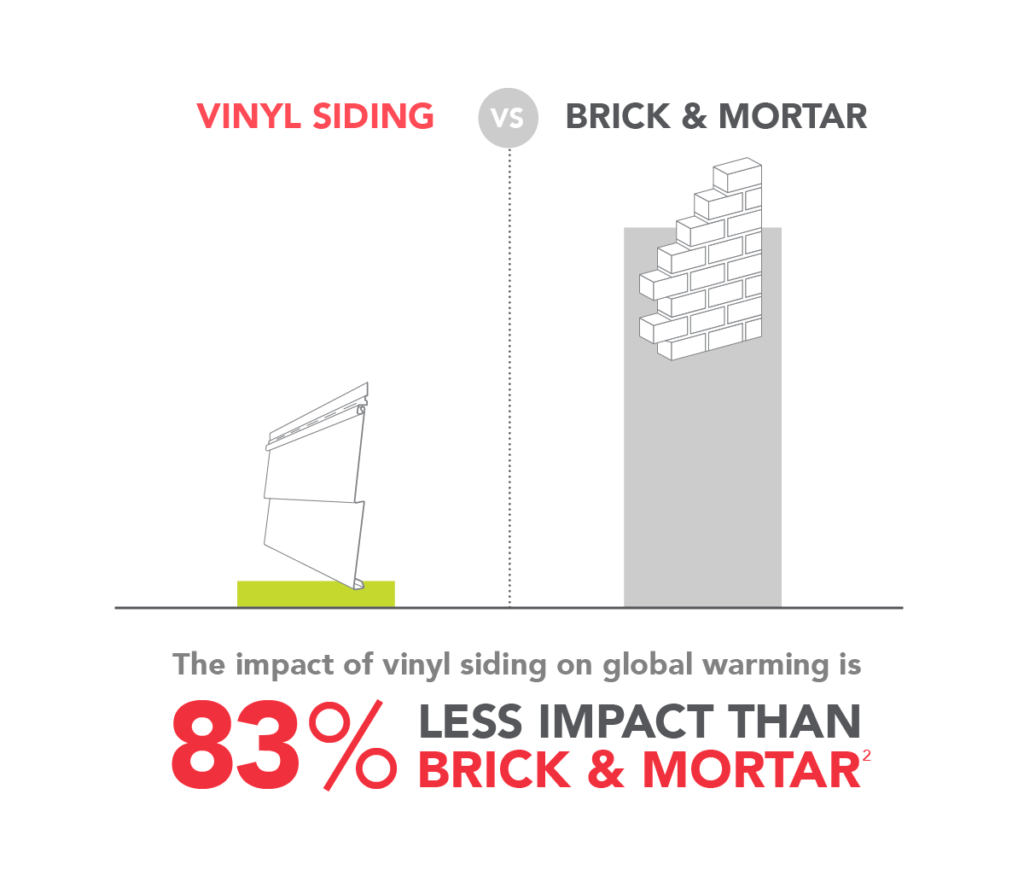

Choosing sustainability means choosing efficiency. And vinyl siding is efficient at every stage, from its resource-conscious manufacturing to its simple maintenance and onward to its easy recycling. Vinyl siding manufacturers are making steady and conscious progress at every step to lessen this material’s carbon footprint. In fact, our carbon emissions have decreased 15% over the life cycle of vinyl siding in the past decade. That’s 9.8 kg of CO2 per 100 square feet. And we continue to invest in meaningful progress with our members to help address global warming with resilient and sustainable building materials1.

More efficiency, less impact on the environment

Reduced Environmental Impact, Same Impressive Resiliency

VSI commissioned a life cycle inventory to assess progress made in the manufacturing processes for vinyl siding.

The industry’s environmental impact reductions since 2011 include:

22%

less electricity

33%

less natural gas

100%

less propane

Recyclable

The scrap and trim recycled from Vinyl plastic manufacturing and fabrication adds up to more than 1 billion pounds per year. Vinyl Cladding’s ability to be recycled back into like products and cross-cycled into different products translates into landfill avoidance. Post-industrial recycled Vinyl is in such demand that its price is indexed in leading plastic industry publications. Scrap Vinyl is recycled into a variety of products: floor tiles and mats, garden hoses, fencing, automotive sound deadening applications, building and construction profiles, pipe, boots, notebook covers, and traffic cones.

Tens of millions of pounds of post-consumer Vinyl are recycled annually. A tremendous additional amount of post-consumer material is not yet available for recycling because it is still in service as pipe, cladding, and other products that last for decades.

Reduced Material Use

Advances in Vinyl formulations have made today’s Vinyl products durable, low-maintenance, and lightweight, all which translate into reduced use (and potential waste) of other materials.

Distribution

Vinyl is lighter to transport than many conventional building materials, reducing the amount of fuel and other resources used for such transportation.

Dioxin from Accidental Fires

Many experts agree that to truly understand a product’s environmental impact, its entire life cycle should be evaluated. This is known as LCA . Environmental effects associated with a product’s manufacture and disposal can be counterbalanced over time by a long, beneficial, low-impact life. For example, impacts associated with the production of vinyl building products such as windows, roofing, and cladding are far outweighed by decades of energy-saving benefits.

- Vinyl products perform favourably in terms of energy efficiency, thermal-insulating value, low contribution to greenhouse gases, low maintenance, and product durability

- Recent life-cycle studies show the health and environmental impacts of vinyl building products generally are comparable to—and can be less than—the impacts of alternatives

Vinyl products are highly resistant to the corrosive conditions found in many landfills. In fact, vinyl is used to make landfill liners and caps because it is so stable.

- Vinyl accounts for less than 0.6% of landfilled waste by weight

- Because it is predominantly used for long-life applications, less vinyl goes to landfills each year than other widely used plastics used in short-term applications (such as plastic bags)

Production

Vinyl is based on commonly available raw materials.

- Pure Vinyl is 57% chlorine, derived from common salt—an abundant and inexpensive resource

- Products like vinyl cladding don’t require the use of paint, stain, or harsh cleansers

- Most vinyl products have long lifespans, usually many decades. Once they are no longer usable, these products can be recycled if local collection and sorting operations are available, or disposed of safely

- Post-industrial and post-consumer vinyl is highly recyclable

- Like other materials used in consumer products, at the end of its life vinyl can be landfilled, or it can be incinerated in modern waste-to-energy facilities and its energy recaptured and reused

Chlorine: Vinyl won’t harm the atmosphere. Once chlorine is processed into vinyl, it is chemically locked into the product more tightly than it was in the salt that it came from. When Vinyl is recycled or landfilled, Chlorine Gas and Hydrochloric Acid (HCl) are not released into the atmosphere.